- Factorial’s first A-sample 40Ah Solstice™ cells showcase significant technical achievement in scaling up all-solid-state battery technology

- The cells are manufactured utilizing a novel dry cathode coating process that is more sustainable, energy-efficient, and cost-effective for battery manufacturing

- Solstice™ all-solid-state cells can boost energy density, up to 80%, progressing towards availability for electric mobility applications.

Factorial Inc. (Factorial), an industry leader in solid-state battery technology, announced today the company’s first Solstice™ all-solid-state battery cells have been scaled to achieve a 40Ah capacity. These automotive-relevant sized A-sample cells are manufactured with a novel dry cathode coating process and showcase the impressive energy density announced in September. This milestone demonstrates progress towards product availability for diverse electric mobility industries.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20241212482983/en/

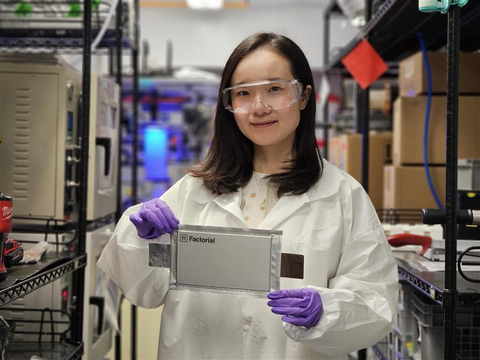

Factorial unveils 40Ah all-solid-state Solstice™ battery cells, using a novel dry cathode coating for higher energy density, sustainability, and scalability. (Photo: Business Wire)

The 100% dry cathode is a novel battery manufacturing process that can eliminate all hazardous solvents in cathode coating. These solvents are not only carcinogenic but also require an energy intensive process to evaporate the chemicals in order to recycle them. In addition to dry coating, Solstice™ eliminates the need for the formation process due to its unique all-solid-state cell design. The coating and formation processes are typically the most energy intensive processes in lithium-ion battery manufacturing. Factorial’s use of the dry coating and all-solid-state chemistry innovations together lower operating costs, reduce energy consumption, and minimize battery production’s environmental impact.

“Breakthrough solid-state battery performance is only relevant if it can be scaled to a size that is viable for commercial use,” said Factorial Co-Founder and CEO Dr. Siyu Huang. “This achievement underscores our team’s technical leadership and unmatched expertise in bringing innovative battery technologies to the high standards of the automotive sector. At 40Ah capacity, our all-solid-state, Solstice™ cells demonstrate the technical maturity, process validation, and scalability required for commercial applications.”

Factorial developed the 40Ah Solstice™ cells at its advanced development center in Massachusetts utilizing custom equipment to establish an in-house dry cathode coating process. Results from lifecycle testing demonstrate that smaller prototypes have already reached over 2,000 cycles.

“The dry electrode coating process is transforming battery manufacturing, introducing significant benefits – such as improved cell performance, faster lead times, and lower costs,” said Factorial CTO and Co-Founder Alex Yu. “Factorial is a leader in advancing this novel manufacturing process for larger-sized cells, which has been a significant challenge for the rest of the market on the road to unlocking one of the most important innovations in battery manufacturing. Coupled with the long cycle life and high energy density, Factorial’s Solstice™ all-solid-state battery cell is poised to give advancements in safety, range, and cost that automakers are looking for.”

This news follows the launch of Solstice™, developed in partnership with Mercedez-Benz to complement Factorial’s industry-leading FEST® (Factorial Electrolyte System Technology). In addition to passenger vehicles, Solstice™ can be used for other applications such as energy storage, consumer electronics and commercial vehicles.

About Factorial Inc.

Founded and headquartered in the United States, Factorial is at the cutting edge of solid-state battery technology, developing solutions that offer longer range per charge, increased safety, and cost competitiveness with conventional lithium-ion batteries. The company’s proprietary solid-state platforms FEST® (Factorial Electrolyte System Technology) and Solstice™ utilize electrolyte innovations that enable safe and reliable cell performance with high-capacity cathode and anode materials. Factorial’s FEST® solid-state batteries are designed to integrate seamlessly with existing manufacturing processes, ensuring scalability and efficiency. The company has established joint development agreements with leading global automakers, including Mercedes-Benz, Stellantis, Hyundai Motor Company, and Kia Corporation. For more information, visit www.factorialenergy.com.

© 2024 Factorial Inc. All rights reserved. Factorial, the Factorial logo, FEST® and Solstice™ are trademarks or registered trademarks in the United States and/or other countries. Other trademarks are the property of their respective owners.

View source version on businesswire.com: https://www.businesswire.com/news/home/20241212482983/en/

Contacts

Media:

Derek Brekken

Antenna for Factorial Energy

factorial@antennagroup.com