As global manufacturing moves towards higher precision and efficiency, China's CNC machining parts industry is poised for new growth opportunities in 2025. Technological upgrades, increased automation, and the demand for stable supply chains from overseas markets are gradually making China a significant CNC parts manufacturing base. For both buyers and manufacturers, understanding the industry structure and processing capabilities is crucial for optimizing supply chains and enhancing competitiveness.

This article provides an overview of the current state of China's CNC machining parts industry from an industry perspective, introducing representative manufacturers in different sub-sectors and their core capabilities and service characteristics to help readers better understand the market landscape and make informed choices.

A List of CNC Machining Manufacturers in Different Fields

|

Company Name |

City |

Year Founded |

Employee Size |

|

Richconn |

Guangdong, China |

2003 |

51-200 |

|

RapidDirect |

Shenzhen, China |

2009 |

201-500 |

|

WayKen |

Shenzhen, China |

2012 |

51-200 |

|

YIJIN Hardware |

Shenzhen, China |

2003 |

51-200 |

|

AT Machining |

Shenzhen, China |

2007 |

11-50 |

|

LVMA |

Wenzhou, China |

2018 |

201-500 |

|

VMT Hardware |

Shenzhen, China |

2008 |

51-200 |

|

LS Manufacturing |

Dongguan, China |

2019 |

51-200 |

|

Worthy |

Dongguan, China |

1998 |

11-50 |

|

JXD Machining |

Xiamen, China |

2001 |

201-500 |

1. Richconn

Richconn is a leading enterprise in China's CNC machining field, founded in 2003 in Dongguan, Guangdong, a bustling manufacturing hub. With a mission to provide "top-tier CNC machining services" the company started as a small factory focused on domestic projects. Through over 20 years of dedicated development and a relentless pursuit of quality, it has earned the long-term trust of clients across various industries.

As an expert in customized precision parts and components, Richconn offers one-stop customized metal machined parts service with product tolerances up to ±0.005mm, suitable for high-end applications such as aerospace and automotive manufacturing. Its core products cover aerospace turbine components and automotive engine accessories, making it a preferred partner for high-end manufacturing with its exquisite craftsmanship. Inquiries and cooperation are welcome.

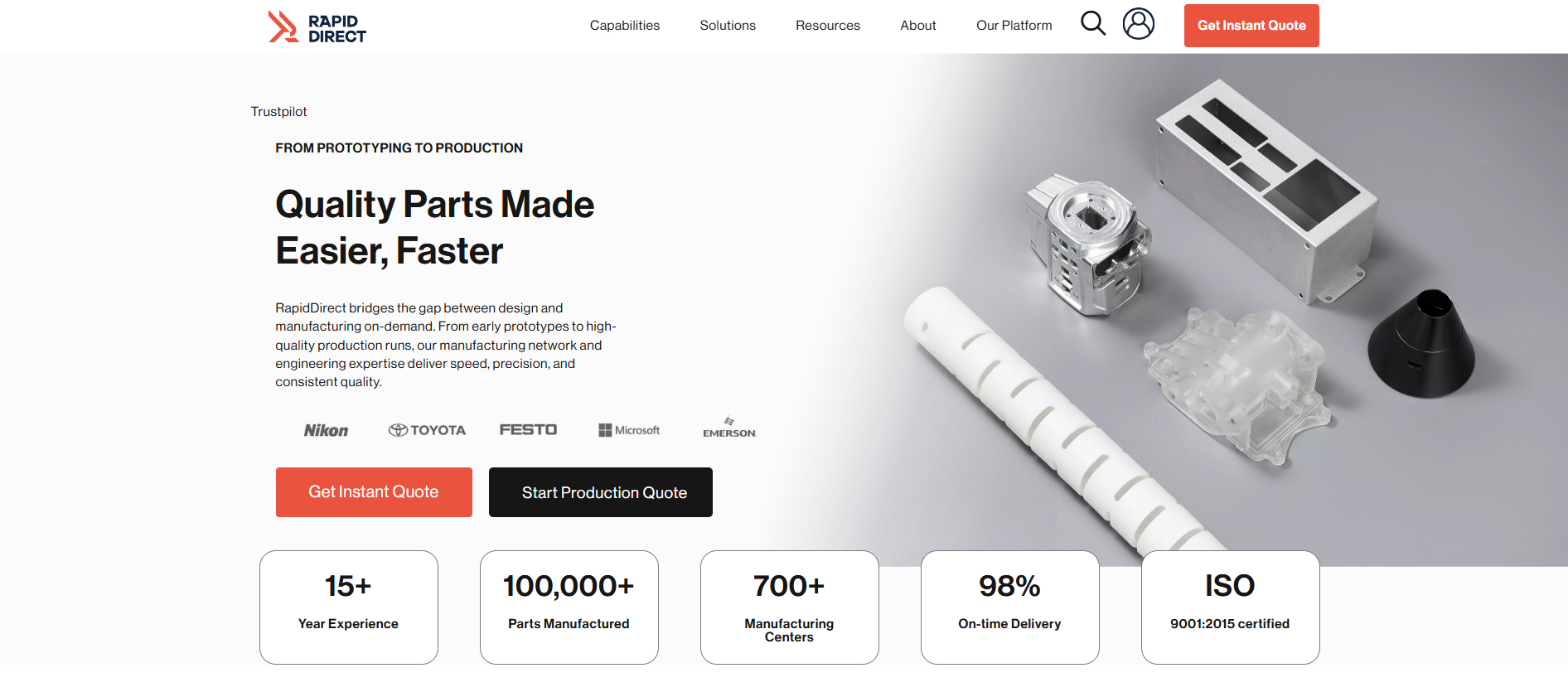

2. RapidDirect

RapidDirect has been deeply rooted in manufacturing since 2009, leveraging AI to revolutionize production and providing global enterprises with a one-stop service for CNC machining, injection molding, sheet metal manufacturing, and 3D printing. Equipped with state-of-the-art multi-axis equipment, it can process materials such as aluminum, steel, brass, and high-performance polymers, covering custom metal milling, turning, and EDM processes, with tolerances down to 0.001 inches, adapting to various design requirements.

Based on ISO 9001 and IATF 16949 certifications, it serves industries such as aerospace, automotive, and medical, providing highly reliable parts, with some metal machined parts delivered within one day. Its online platform supports instant quotes and inquiries, with engineers providing full support from rapid prototyping to mass production. With flexible services, it helps companies save time and costs, and achieve efficient implementation, making it the preferred partner for precision manufacturing.

3. WayKen

WayKen is a leading CNC machining manufacturer in Shenzhen, with a 35,000-square-foot factory equipped with 16 high-performance machining machines operating 24/7. It completes over 300 machining projects monthly, producing more than 20,000 precision metal machined parts, and can flexibly undertake all scenarios from complex prototyping to mass production.

The company's core services cover CNC milling, turning, 5-axis machining, and EDM, with machining tolerances up to ±0.0005 inches and surface roughness control between 0.2-3.2μm. It is compatible with metals such as aluminum, stainless steel, and titanium alloys, as well as over 30 types of engineering plastics, meeting diverse material processing needs.

As a company with 20 years of industry experience, WayKen's team consists of over 60 highly qualified technical personnel, providing clients with one-stop customized solutions from design to delivery. Its service network covers multiple industries including industrial, medical, automotive, and aerospace.

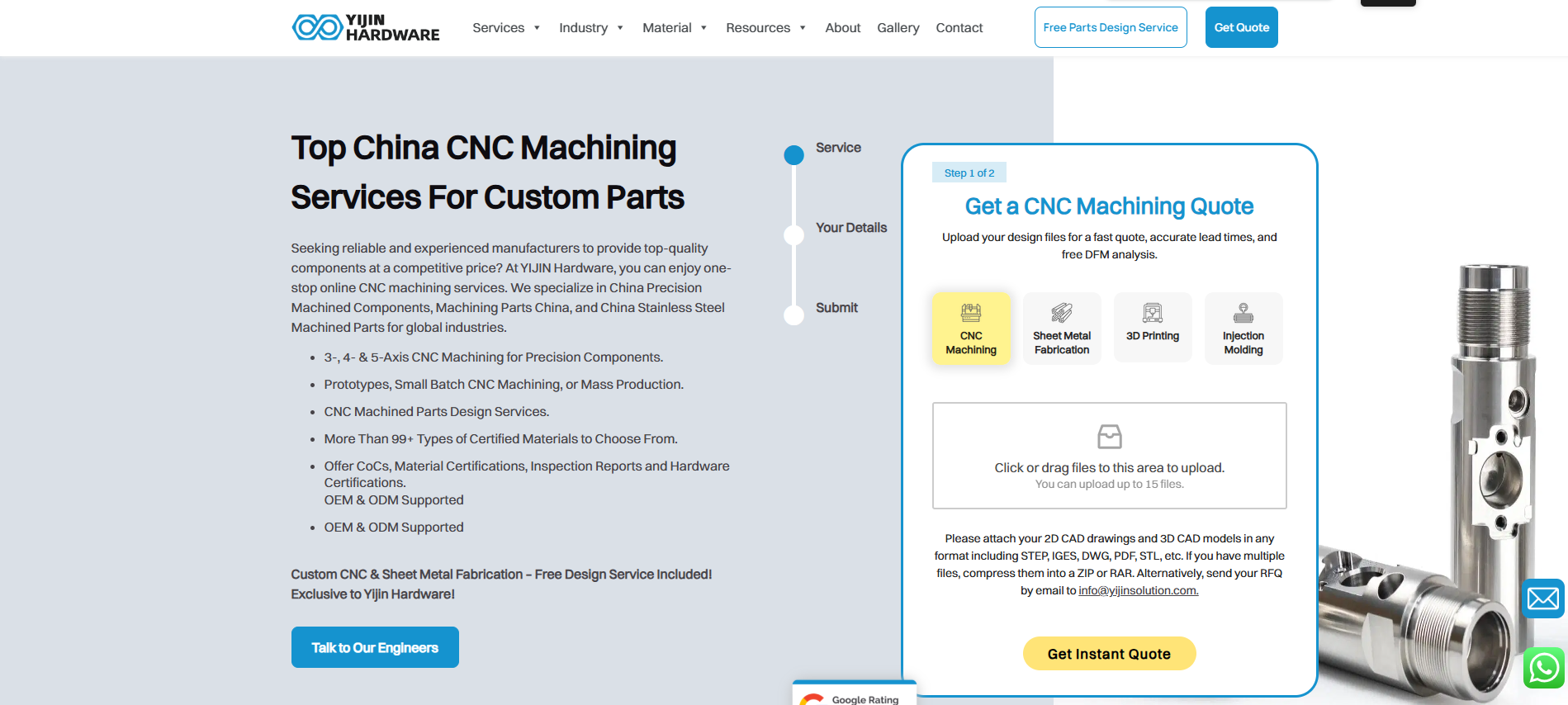

4. YIJIN Hardware

Yijin Hardware established in 2003, boasts a factory area of over 25,000 square meters and more than 100 employees. Equipped with 3-5 axis CNC machining centers, Swiss-type lathes, and other high-precision equipment, supplemented by advanced testing instruments such as Zeiss coordinate measuring machines, its production facilities are comprehensive.

The company specializes in customized metal CNC milling and turning services, as well as special screws and fasteners. With precise tolerances and support for full-process customization, its products are suitable for various industries including aerospace, high-speed rail, and medical. Leveraging a rigorous quality control system and exquisite craftsmanship, the company provides reliable precision metal machined parts to customers, earning widespread recognition both domestically and internationally.

5. AT Machining

AT Machining Founded in Shenzhen in 2007, AT Machining boasts over 50 CNC machines (including 3-5 axes), providing milling, turning, and laser cutting services with tolerances down to ±0.005mm. It is compatible with over 100 metal and plastic materials, saving 30-50% in costs.

The company has no minimum order quantity and offers post-processing services such as anodizing and powder coating. Serving the automotive, medical, and aerospace industries, it is ISO 9001 certified. Prototype delivery takes 2-3 weeks, and mass production takes 4 weeks. Expedited and one-stop customization services are available.

6. LVMA

LVMA was established as an export brand for CNC machined parts in 2018. Its factory, founded in 2004, boasts over 20 years of production experience. As an integrated industrial and trading manufacturer in Zhejiang, it offers a 10% price advantage compared to suppliers in Guangdong, while maintaining comparable quality, resulting in outstanding cost-effectiveness.

Leveraging over 500 advanced pieces of equipment (including a 5-axis, 20kW laser cutter) and a team of over 300 engineers, LVMA integrates multiple core processes such as CNC machining and injection molding. Having passed ISO triple-system certification and CE certification, LVMA achieves a 99.9% first-pass yield rate, ensuring high-precision and stable output.

Focusing on non-standard customization needs in industries such as electrical, new energy, and auto parts, LVMA provides 24/7 service response and 99.9% on-time delivery. Coupled with a digital platform for full-lifecycle service and a low-carbon production model, LVMA delivers highly adaptable solutions to global customers.

7. VMT Hardware

VMT Established in Shenzhen in 2008, VMT has been deeply involved in the field of precision metal parts customization and assembly for 13 years, holding ISO9001 and IATF16949 certifications and 11 patents. From process development to mass production delivery, VMT adheres to the philosophy of "making every customized part perfect."

The factory covers an area of 6,000 square meters and is equipped with over 100 high-end machines, supplemented by a comprehensive quality control system (automatic testing equipment, 2D/3D projectors), achieving zero-defect control from DFM review to final inspection. VMT provides one-stop solutions for CNC machining, forging, die casting, and welding, with a library of 7,692 non-standard parts, and has served over 5,246 mass-produced models.

8. LS Manufacturing

LS Manufacturing has been deeply rooted in the industry for over 15 years, delivering over 80,000 projects and holding multiple international certifications. Tolerances are accurate to ±0.005mm. Features include free DFM analysis and instant quotations, support for multiple file formats (secure and confidential), 72-hour fast delivery, and 1-day delivery for urgent orders.

It covers diverse processes such as Medical Cnc Turning, vacuum casting, and extrusion, adapting to over 80 materials and over 40 surface treatments. With 24/7 engineering support and 1-day after-sales response, it serves multiple industries including CNC Turning Medical and automotive parts, providing flexible one-stop customization from prototype to mass production.

9. Worthy

Worthy is a Dongguan's famous CNC Machined Parts Manufacturer, with its core feature of "7x24-hour operation," breaking industry norms for service timelines and responding to customer needs anytime, anywhere. Starting as a small workshop, it has expanded beyond simple processing, overcoming growth challenges by offering new services such as sheet metal manufacturing and laser cutting.

Worthy's clients span multiple countries globally, including Japan, the US, Germany, and Russia. In 2015, it streamlined operations across four business divisions within a 1500㎡ factory, maintaining steady growth for many years.

10. JXD Machining

JXD Machining provides end-to-end customized services from prototype design to mass production. Its features include support for over 100 diverse materials such as metals, plastics, and ceramics, combined with over 20 professional surface treatment processes. It is also certified by four international standards, including ISO 9001 and IATF 16949, and supports on-site factory visits, ensuring transparent and traceable quality.

The company specializes in Metal Machined Parts, precisely adapting to the needs of industries such as aerospace, medical, electronics, and consumer products. With its rigorous end-to-end quality control and efficient production system, it can flexibly handle both high and low batch orders, providing comprehensive support from design analysis to on-site delivery, becoming a trusted precision manufacturing partner for global clients.

Conclusion

This article has compiled a list of high-quality Chinese CNC machining manufacturers across various sectors, including aerospace, medical, automotive, and new energy. However, selecting a suitable partner is no easy task; it requires in-depth research and scenario verification to confirm their industry suitability and the degree of alignment with one's own needs.

Besides core technological strength and advanced machining equipment, a manufacturer's adherence to industry standards and the speed of their customized service response are also crucial considerations. Selecting partners through actual cooperation ensures both part precision and alignment with industry characteristics, providing strong support for the efficient advancement of projects.

Media Contact

Company Name: Zhejiang LVMA Co., Ltd.

Email: Send Email

Country: China

Website: https://www.lvma-cnc.com/