- Dentists and labs can use proprietary SmileGuard resin to 3D print bite splints, night guards, and mouth guards in the office in as little as one hour, allowing same-day delivery

- Compared to other 3D printed materials, SmileGuard delivers a superior blend of strength and comfort in a high-clarity product that is easy to keep clean

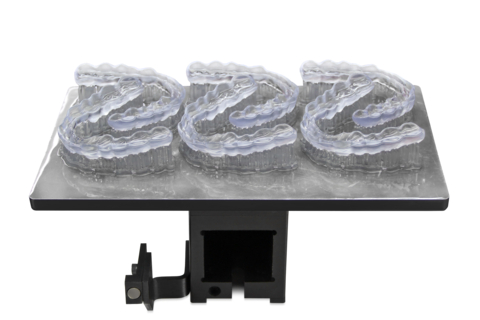

- 3D printed on Desktop Health’s high-accuracy Einstein™ 3D printing technology, Smileguard is easy to print, process, polish, and place

Desktop Health, a healthcare business within Desktop Metal, Inc. (NYSE: DM) committed to developing 3D printing solutions for personalized medicine, today announced it has received U.S. Food and Drug Administration (FDA) 510(k) clearance of SmileGuard resin, a breakthrough light-curable biocompatible material for the fabrication of strong and flexible bite splints and other orthodontic and dental appliances.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20221006005202/en/

Desktop Health is launching SmileGuard, a breakthrough light-curable biocompatible material for 3D printing strong and flexible bite splints and other orthodontic and dental appliances. Dentists and labs can use SmileGuard to 3D print bite splints, night guards, and mouth guards in the office in as little as one hour, allowing same-day delivery. (Graphic: Business Wire)

SmileGuard resin, which is now available for ordering and shipping, solves a challenge among 3D printed bite sprint solutions in the marketplace today. Among the available options, the strongest materials are often uncomfortable to patients, while softer materials are often not as durable.

In development for more than two years, SmileGuard resin, however, offers a superior blend of both strength and comfort, custom fit to a patient’s specific dental profile and needs. At the same time, it offers high impact resistance to teeth grinding, clenching, temporomandibular disorders (TMD), and abrasions.

“Every year, dentists and orthodontists prescribe millions1 of bite splints or night guards to prevent patients from clenching and grinding their teeth, which can cause pain, headaches, sleep disruption and also damage teeth,” said Ric Fulop, Founder and CEO of Desktop Metal. “Made with traditional techniques, these devices typically require several steps and visits – from the time to diagnose, make an impression and manufacture, to the custom-fitting to the patient. Now dentists and orthodontists have a fast, easy and reliable way to produce custom-made devices while the patient waits at the office. This is another milestone in dental innovation.”

The Digital Difference

Traditional analog methods to manufacture night guards require dental impressions that are sent to a lab to produce. At the lab, a splint is thermoformed on a model, which must be created, or it’s milled out of a puck and checked on a model for fit. Then, it must be polished and shipped to the dentist, with the complete turnaround time often averaging 2-3 weeks and requiring multiple patient visits.

With Desktop Health’s digital 3D printing workflow, SmileGuard resin can be used to manufacture night guards in as little as an hour and delivered to the patient the same-day. The patient is scanned in minutes during an office visit, where easy-to-use software enables the device to be designed and printed. Polishing takes just minutes to achieve a high shine.

3D printed bite splints and night guards are a fast growing segment in digital dentistry and one of the top 3 most common 3D printed dental applications. More than 45% of dental labs and clinicians are currently 3D printing bite splints and night guards.2

Desktop Health’s Growing Leadership in 3D Printed Dental Solutions

SmileGuard resin joins a growing portfolio of Desktop Health dental solutions for both dental labs and dental professionals, including:

- The EinsteinTM 3D printer, designed specifically for dental professionals, delivers key features essential to superior 3D printing: accuracy, speed, and versatility. The Einstein’s NanoFit 385 technology delivers parts with stunning clarity, a perfect fit, and an impressive finish. Equipped with Hyperprint™ technology, which harnesses the power of heat and a closed-loop process, the Einstein prints up to 50 percent faster speed than its predecessor.

- FlexceraTM FDA-cleared materials for removable and restorative indications. Flexcera Base leverages proprietary long-chain chemistry to deliver one of the strongest dental resins on the market for the fabrication of 3D printed denture bases. Flexcera Smile Ultra+ provides the perfect blend of strength and flexibility coupled with a natural-looking, lifelike luster for a wide range of permanent and temporary dental restorations including, crowns, inlays, onlays, bridges, veneers, full and partial dentures.

About Desktop Health

Desktop Health, a healthcare business within Desktop Metal and based in Burlington, Massachusetts, is leveraging additive manufacturing and advanced materials to personalize patient care. Desktop Health is vertically integrated to develop, manufacture and commercialize applications across a range of healthcare specialties, including dental, medical and biofabrication. For more on Desktop Health, visit www.desktophealth.com.

About Desktop Metal

Desktop Metal, Inc., based in Burlington, Massachusetts, is accelerating the transformation of manufacturing with an expansive portfolio of 3D printing solutions, from rapid prototyping to mass production. Founded in 2015 by leaders in advanced manufacturing, metallurgy, and robotics, the company is addressing the unmet challenges of speed, cost, and quality to make additive manufacturing an essential tool for engineers and manufacturers around the world. Desktop Metal was selected as one of the world’s 30 most promising Technology Pioneers by the World Economic Forum, named to MIT Technology Review’s list of 50 Smartest Companies, and the 2021 winner of Fast Company’s Innovation by Design Award in materials and Fast Company’s Next Big Things in Tech Award for sustainability. For more information, visit www.desktopmetal.com.

Forward-Looking Statements

This press release contains certain forward-looking statements within the meaning of the federal securities laws. Forward-looking statements generally are identified by the words “believe,” “project,” “expect,” “anticipate,” “estimate,” “intend,” “strategy,” “future,” “opportunity,” “plan,” “may,” “should,” “will,” “would,” “will be,” “will continue,” “will likely result,” and similar expressions. Forward-looking statements are predictions, projections and other statements about future events that are based on current expectations and assumptions and, as a result, are subject to risks and uncertainties. Many factors could cause actual future events to differ materially from the forward-looking statements in this document, including but not limited to the risks and uncertainties set forth in Desktop Metal, Inc.'s filings with the U.S. Securities and Exchange Commission. Forward-looking statements speak only as of the date they are made. Readers are cautioned not to put undue reliance on forward-looking statements, and Desktop Metal, Inc. assumes no obligation and does not intend to update or revise these forward-looking statements, whether as a result of new information, future events, or otherwise.

__________________________

1JADA, Dental Splint Prescription Patterns: A Survey, 1995

2LMT Retrospective Survey, 2021

View source version on businesswire.com: https://www.businesswire.com/news/home/20221006005202/en/

Desktop Metal announced it has received U.S. Food and Drug Administration (FDA) 510(k) clearance of SmileGuard resin, a breakthrough light-curable biocompatible material for the fabrication of strong and flexible bite splints and other dental appliances.

Contacts

Media Relations

Sarah Webster

(724)516-2336

Sarahwebster@desktopmetal.com

Investor Relations

Jay Gentzkow

(781) 730-2110

jaygentzkow@desktopmetal.com